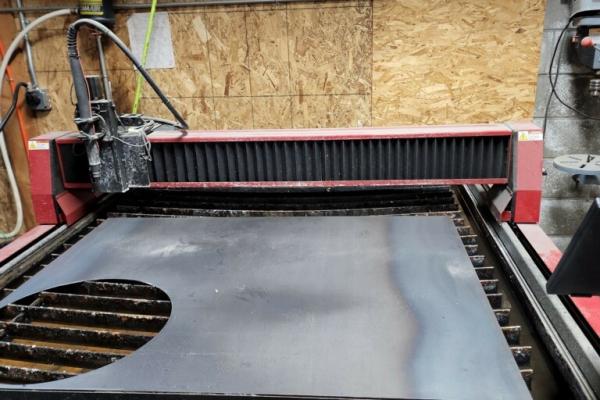

Success Stories, Torchmate Reviews, and Testimonials From Customers from Around the World!

Torchmate has thousands of satisfied customers across the globe. Below you'll find many of their success stories and how they used their Torchmate machines to build their business or help their organization!