About Us

Torchmate is Now Owned by Lincoln Electric®

Lincoln Electric is the world leader in the design, development and manufacture of arc welding products, robotic arc welding systems, plasma and oxy-fuel cutting equipment and has a leading global position in the brazing and soldering alloys market. Headquartered in Cleveland, Ohio, Lincoln Electric has 56 manufacturing locations, including operations and joint ventures in 20 countries and a worldwide network of distributors and sales offices covering more than 160 countries. For more information about Lincoln Electric and its products and services, visit the Company’s website at http://www.lincolnelectric.com.

Affordability, Service, Quality and Commitment

The Kunz family began selling its first shape cutting machines, called the Torchmate, back in 1979. William Kunz Sr. had spent his childhood learning about working with metal and working on hot rods. It was his love of automobiles and tinkering that led to the first Torchmate. After having read about Pantograph Flame Cutting machines in an automotive magazine, Bill set out to bring that technology to the common shop. In his mind there was no reason why this technology had to cost $1,400+ (which was a lot of money 30 years ago) considering it was mostly hobbyists buying them. One year after having read about other companys' machines, the very same magazine wrote an article about Bill’s Torchmate Pantograph Machine Kits and how they were changing the industry as they were being offered at a then astonishing $400. The Torchmate product line and the companies that support it have been built on this same premise that technology should not only be available to the metalworking elite.

The Kunz family began selling its first shape cutting machines, called the Torchmate, back in 1979. William Kunz Sr. had spent his childhood learning about working with metal and working on hot rods. It was his love of automobiles and tinkering that led to the first Torchmate. After having read about Pantograph Flame Cutting machines in an automotive magazine, Bill set out to bring that technology to the common shop. In his mind there was no reason why this technology had to cost $1,400+ (which was a lot of money 30 years ago) considering it was mostly hobbyists buying them. One year after having read about other companys' machines, the very same magazine wrote an article about Bill’s Torchmate Pantograph Machine Kits and how they were changing the industry as they were being offered at a then astonishing $400. The Torchmate product line and the companies that support it have been built on this same premise that technology should not only be available to the metalworking elite.

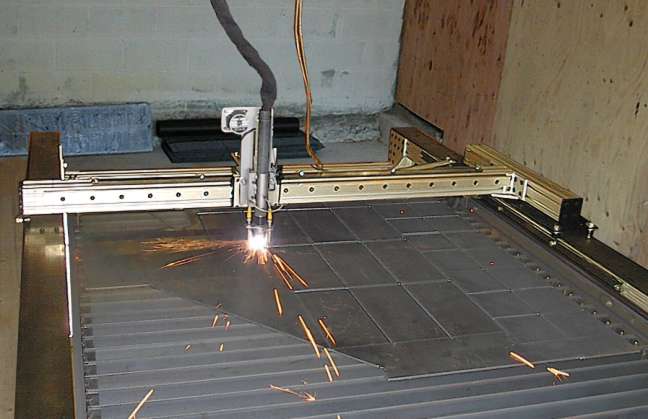

Bill sold thousands of the Torchmate Pantograph machines over the next 18 years. In 1997, Bill launched the Torchmate line of CNC (Computer Numerically Controlled) Cutting Machines. What started out in 1979 as a Pantograph machine using a magnet to guide an oxy-fuel torch around a metal template had turned into a fully automated two axis cutting CNC table guiding a plasma cutter. While plasma cutting technology had previously been expensive and out of reach for most shops, major breakthroughs were being made that allowed the cutters' use on economical tables such as the Torchmate. Even today, the original Torchmate CNC Plasma Cutting Table is still sold as a kit, which is known as the Torchmate 1.

Bill sold thousands of the Torchmate Pantograph machines over the next 18 years. In 1997, Bill launched the Torchmate line of CNC (Computer Numerically Controlled) Cutting Machines. What started out in 1979 as a Pantograph machine using a magnet to guide an oxy-fuel torch around a metal template had turned into a fully automated two axis cutting CNC table guiding a plasma cutter. While plasma cutting technology had previously been expensive and out of reach for most shops, major breakthroughs were being made that allowed the cutters' use on economical tables such as the Torchmate. Even today, the original Torchmate CNC Plasma Cutting Table is still sold as a kit, which is known as the Torchmate 1.

In late 1997, Bill was swamped and enlisted his son, who shares his same name, to assist in selling the new Torchmate CNC product line. Bill Kunz Jr. had moved to Lake Tahoe after having graduated from West Virginia University with a degree in Recreation and Parks Management. He spent his working career in Sales and Service industries as well as building his own company. The entrepreneurial spirit runs deep in this family. Over the next decade the two Bills would experience growth beyond what either of them ever could have predicted. Once again, they never lost focus on the goal of bringing the latest technology to market at the most affordable price and providing the best service possible to go along with their customers' purchases.

In early 2001 the Torchmate product line grew as the Kunzes offered a new model called the Torchmate 2. Rather than forcing the customer to fabricate the entire machine the Torchmate 2 used an extruded aluminum gantry. This cut the fabrication time involved in building a machine down from 40 hours to just 16 hours to simply fabricate a support table. The Torchmate 2 was also held down so that it could be used vertically, upside down or for 3-D cutting. By adding a third axis and supporting the gantry from under the guide rails, the Torchmate functionality was expanded into cutting wood, plastic, foam and other materials with a router as well as the use of a drill. Over the following years improvements were made and another axis was added thus allowing for the birth of yet another model known now as the Torchmate 3 which offered a full aluminum extrusion frame therefore cutting assembly time down to less than a day. All the while the Torchmate product line remained under the $10,000 price point which was previously unheard of for this quality of CNC equipment.

The Torchmate 2 and Torchmate 3 brought forth more explosive growth and the two Bills realized quickly that the only way to continue to keep up was to begin to hire employees. Up to this point, the Torchmate products were strictly the work of Bill Sr. in his basement office in the Washington DC area and Bill Jr. operating out of his garage in Reno. While most companies would struggle because of the distance between partners, the Kunzes thrived. One person led to another who led to another and one office led to another which led to another. All the while no one has ever lost sight of the fact that the Torchmate product line had to remain affordable, be of the highest quality and its representatives must always be committed to superior service.

The Torchmate 2 and Torchmate 3 brought forth more explosive growth and the two Bills realized quickly that the only way to continue to keep up was to begin to hire employees. Up to this point, the Torchmate products were strictly the work of Bill Sr. in his basement office in the Washington DC area and Bill Jr. operating out of his garage in Reno. While most companies would struggle because of the distance between partners, the Kunzes thrived. One person led to another who led to another and one office led to another which led to another. All the while no one has ever lost sight of the fact that the Torchmate product line had to remain affordable, be of the highest quality and its representatives must always be committed to superior service.

New products have continued to be added to the Torchmate line. The Torchmate X was brought to market with the idea of competing with the $50,000+ machines on the market for half the price. This is done by utilizing the same technology which the Torchmate itself uses, automation. These days six axis welding robots are used to fabricate these tables and they are simply craned into place at the customer's location. In 2010, the new Torchmate 2x2 CNC Prototyping System was introduced with the sole purpose of putting CNC technology to work in your home shop or garage. Even with over 30,000 square feet of production space and offices along with 73 dedicated employees, Torchmate stands by its roots. We invite you to click on the links below to view our team and the environment in which these amazing machines are built. Now more than ever before, there is a Torchmate machine to fit every budget and every level of production. Give us a call toll free at (866)571-1066 and let one of our professionals help you determine which Torchmate best fits your needs.

New products have continued to be added to the Torchmate line. The Torchmate X was brought to market with the idea of competing with the $50,000+ machines on the market for half the price. This is done by utilizing the same technology which the Torchmate itself uses, automation. These days six axis welding robots are used to fabricate these tables and they are simply craned into place at the customer's location. In 2010, the new Torchmate 2x2 CNC Prototyping System was introduced with the sole purpose of putting CNC technology to work in your home shop or garage. Even with over 30,000 square feet of production space and offices along with 73 dedicated employees, Torchmate stands by its roots. We invite you to click on the links below to view our team and the environment in which these amazing machines are built. Now more than ever before, there is a Torchmate machine to fit every budget and every level of production. Give us a call toll free at (866)571-1066 and let one of our professionals help you determine which Torchmate best fits your needs.

In 2011, Torchmate was acquired by Lincoln Electric.

In 2016, Torchmate released the all new Torchmate 4400 and 4800 cnc plasma tables. These machines are all in one units designed and built by Lincoln Electric. The systems include the table, motion controller, and plasma cutter all built by Lincoln Electric.

In 2018, the Torchmate 5100 was released. This is an industrial 5x10 cnc plasma cutting table, capable of handling high definition plasma cutters.

In 2019, Lincoln Electric Cutting Systems is registered to ISO 14001 for all activities related to the design, manufacture, and distribution of flexible, automated metal cutting solutions for various industries, including support activities at this location. Please click here for the ISO 14001 certificate of registration.